RESTORATION PROGRESS

Work to rebuild the car started in late 2006. The underframe had been inspected and unfortunately none of the main timbers could be reused due to damage from rusted ironwork that had been left in situ when the running gear was removed. The rust had expanded and cracked the pitch pine.

Here one end of a solebar is shown showing the cracks caused by the rust. New pitch pine couldn't be found at that time so some lovely Canadian Douglas Fir was used instead and after all the joints had been marked and cut the frame was trial assembled for the first time.

Here Paul Brearley, Jim Soper and Bernard Donald stand in front of the underframe.

The next step was to drill the holes for the truss rods to go through. These are angled in 2 dimensions and the 18" long drill had to be carefully set up.

The frame was then finally assembled upside down and all the various plates and straps fitted before being painted.The corner joints are a careful mix of interlocking mortises and tenons that also hold the corner pillars in. They are held together by oak pegs. When the frame was square the positions of the 4 axleboxes were surveyed and marked so that the wheels will be square when they are fitted.

Once the various plates had been fitted the platform bearers were cut and trial fitted. The sizes and shapes of these had been worked out by a combination of photographic information and careful examination of all the marks left on the old underframe. One dimension was found by measuring the length of a rusted coachbolt that had been bent over and left in situ with its nut still in place.

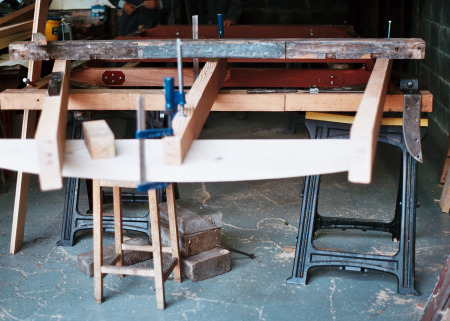

Finally in this phase the frame was turned the right way up and placed on four supports that were in the same locations as the axleboxes will be. This is done so that as parts are added the correct stresses can be built in to ensure that the tram stays level and square as more parts are fitted.

Here the frame is shown being checked for twist. The truss rods and support pillars are original. They have just had new ends welded on to replace the badly rusted areas inside the solebars. Eight of the underframe parts had to be replaced but we were able to retain the four diagonals.

Dismantling/mock up phase 2005/6 Restoration Progress 2007/8